Conformal Cooling

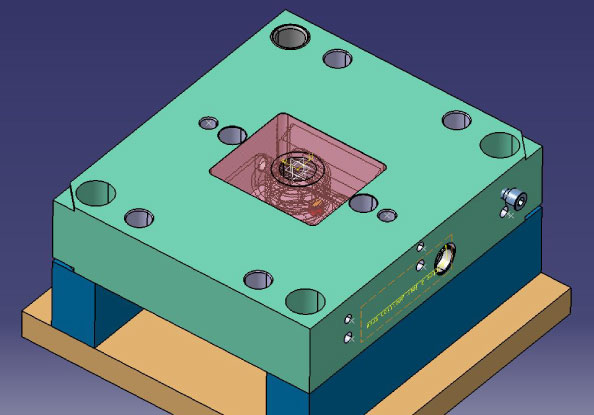

Get cooling channels

in just 1 process thanks to 3D printing

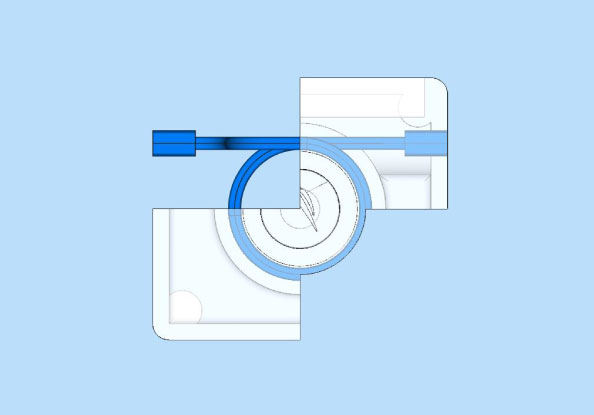

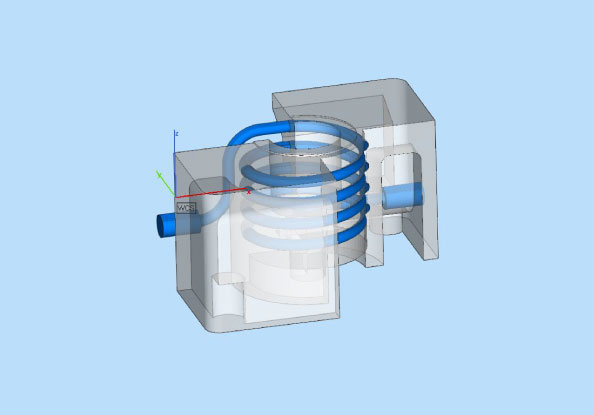

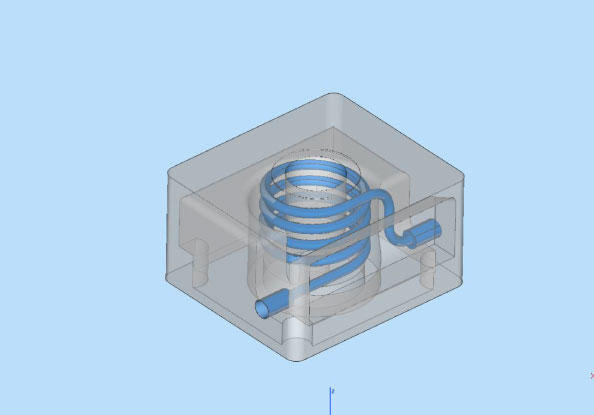

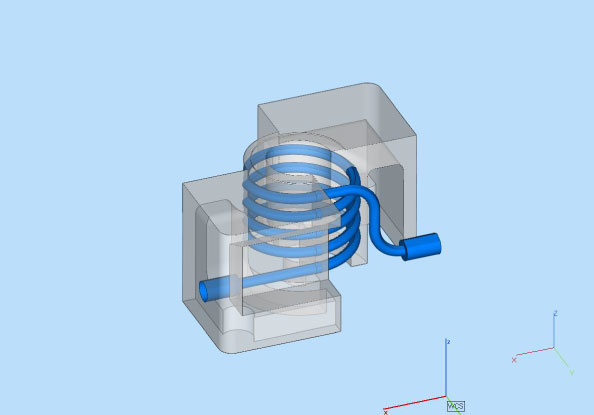

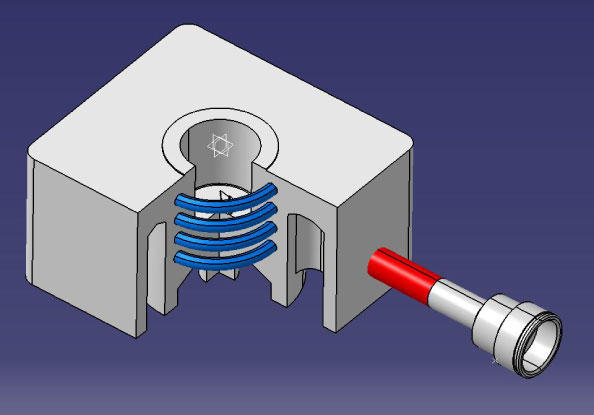

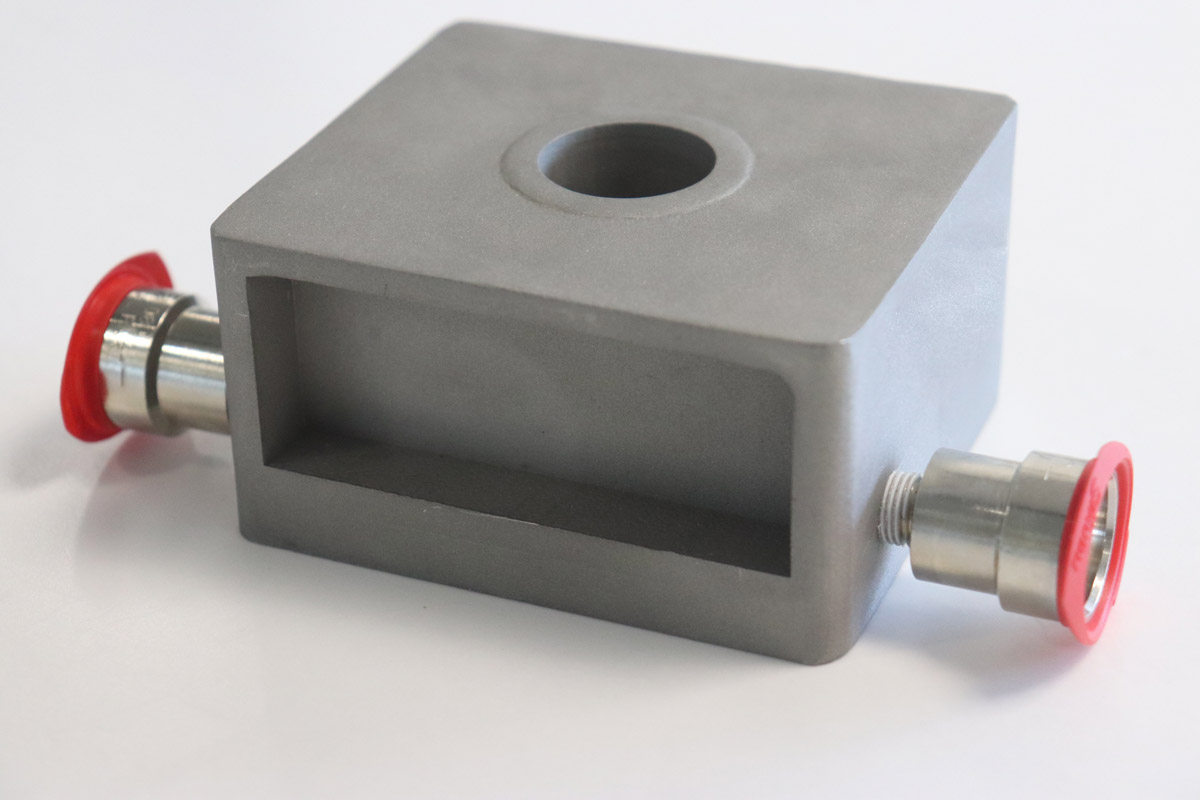

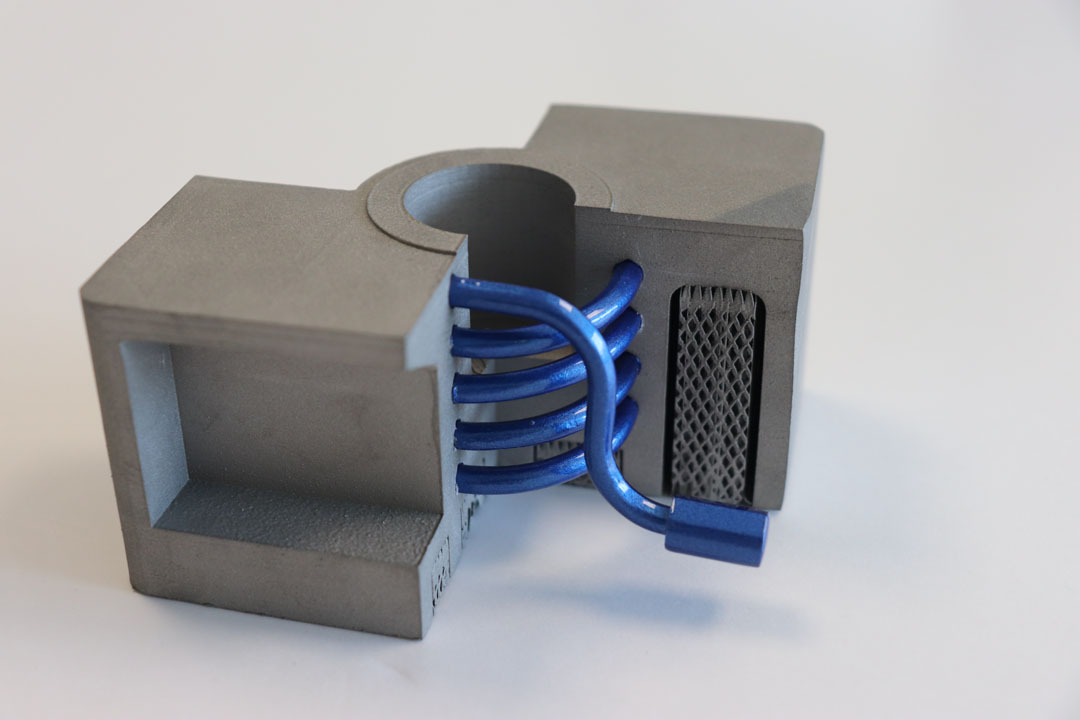

Conformal cooling is a process which consists in directly creating cooling channels of complex shapes in a room for better thermal regulation. All thanks to 3D printing and in particular metal fusion

Learn more about metal fusionA unique process ideal for mold makers

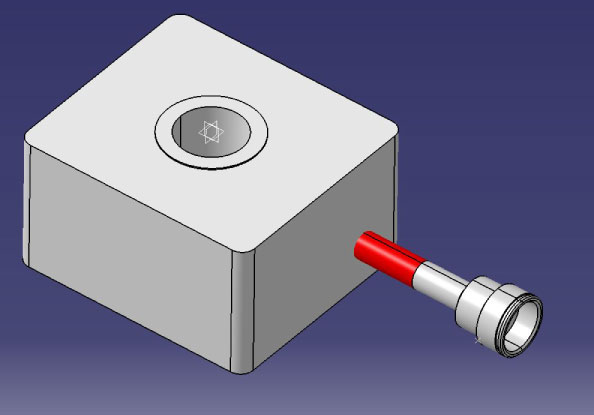

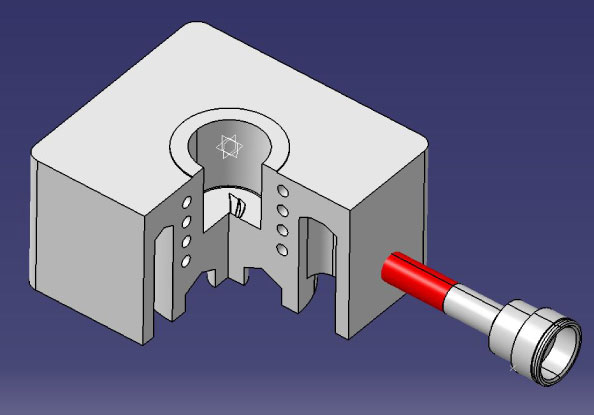

The problem with traditional cooling methods is that they cannot reach the places where the cooling channels are needed. Traditional machining often reaches these limits on complex parts. With additive manufacturing this is no longer a problem, mold makers can now create better cooling circuits for their parts.

More efficient thermal regulation

By using SLM technology and conventional machining together, we can fabricate cooling channels in a mold where traditional machining alone reaches these limits. This technological process thus brings many advantages:

– A reduction in production costs

– More efficient thermal regulation

– Reduced cycle times

– Optimized material performance

– Reduced warping