Outillage rapide

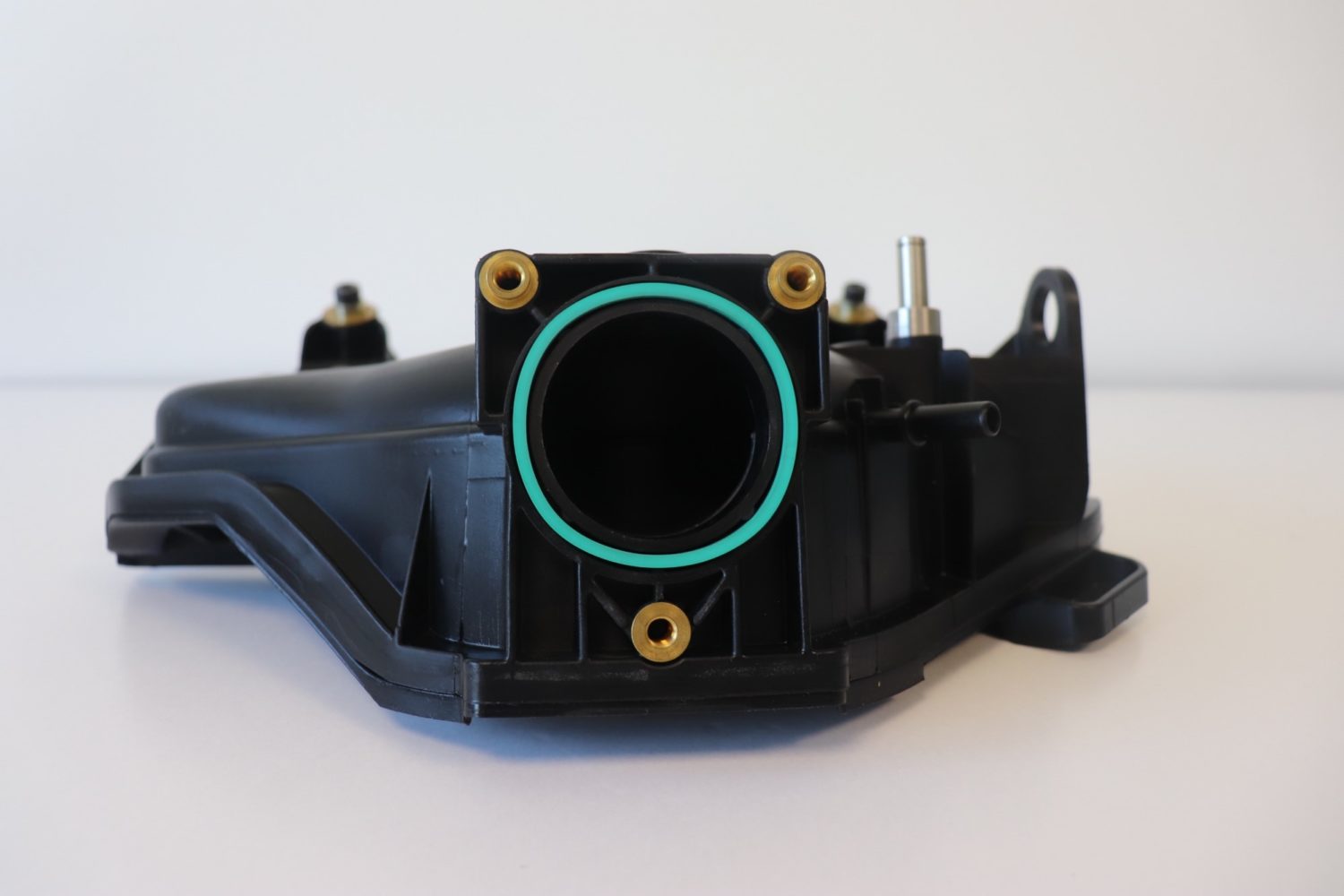

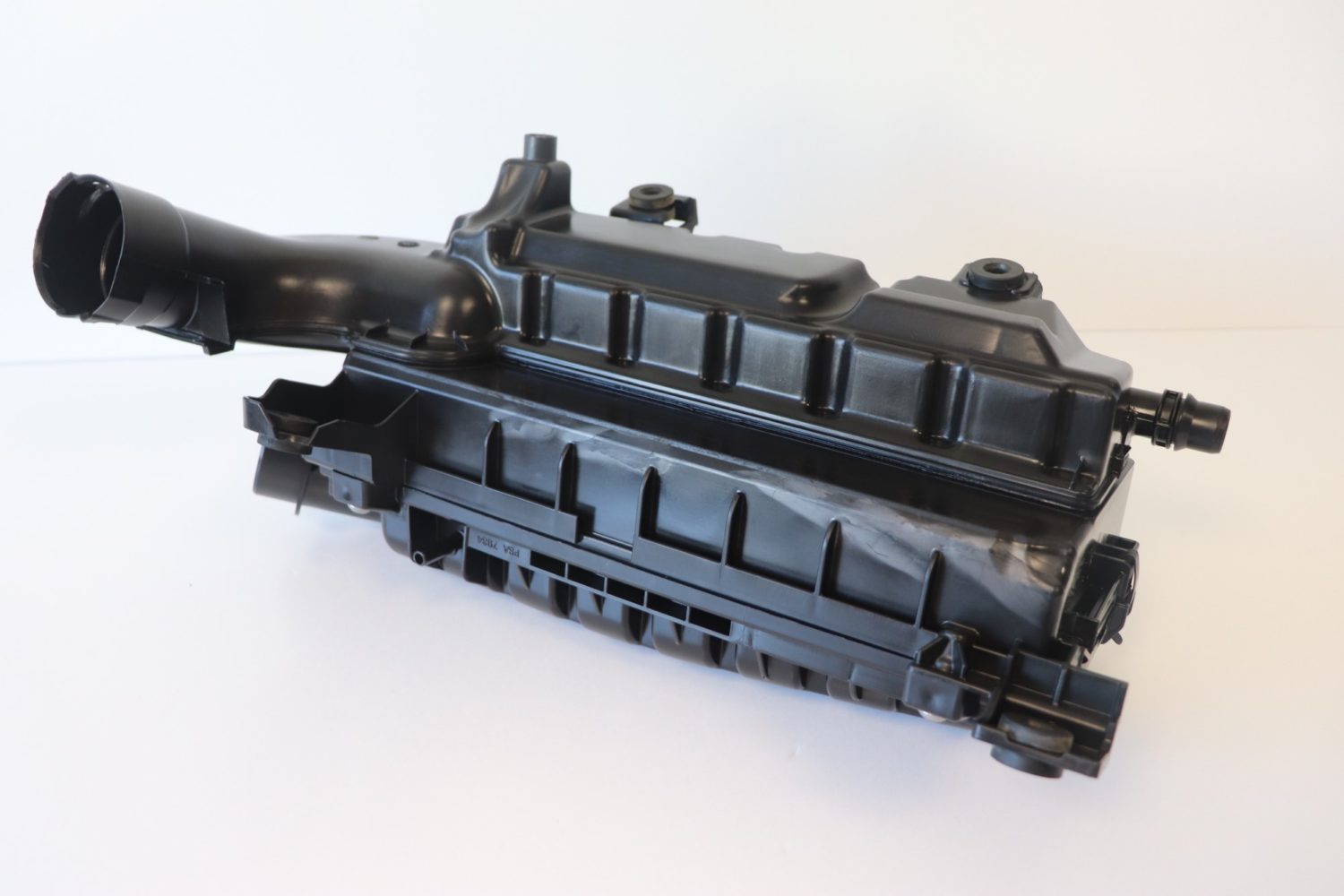

Injection Plastique

Prototypes, small series

in a record time

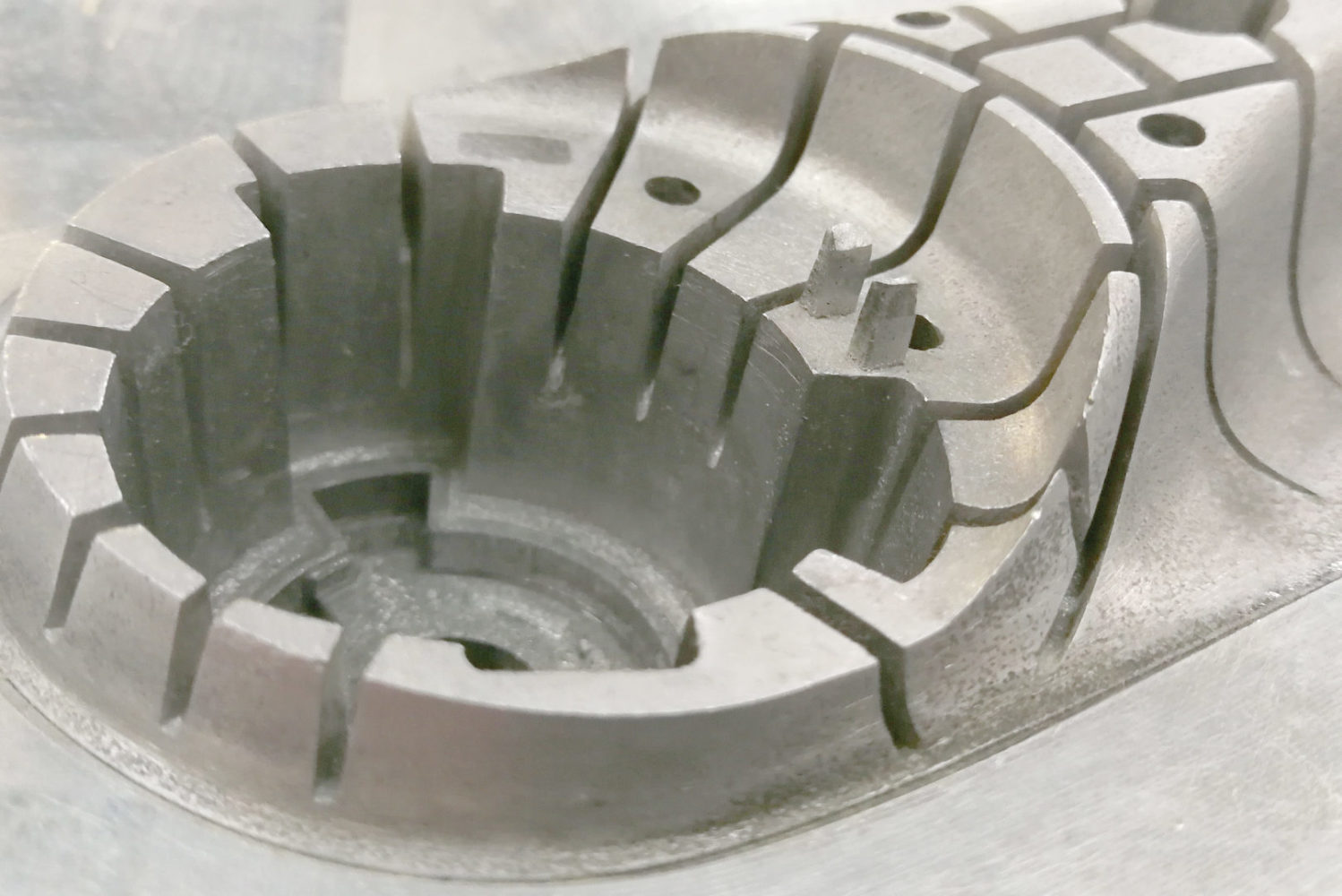

Equipped with metal 3D printers, and CNC machining centers, we ensure the design, production, finishing, and development of molds and plastic injection tools.

We also have 10 injection molding machines to ensure the production of your plastic parts.

Our work methodology, our combination of “hybrid” molds (mold made by machining and/or metal additive manufacturing) allow us to provide you with prototype plastic parts and small series in record time (1 to 2 weeks).

Quick Tools

Advantages

Rapid injection tooling has the following advantages:

– Very short deadlines

– Cost reduction

– Changes possible quickly

– The more complex the parts, the more advantageous the technology

– Reliability of the process (little human intervention)

– Possibility of injecting several thousand parts