Smoothing 3D printed parts

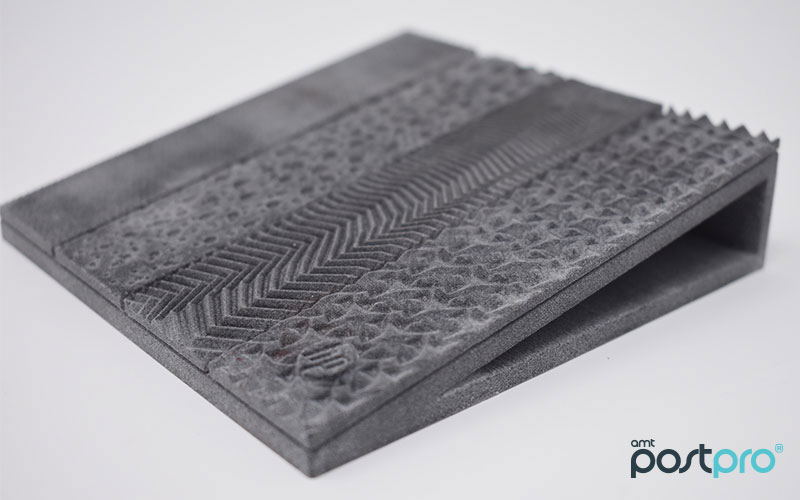

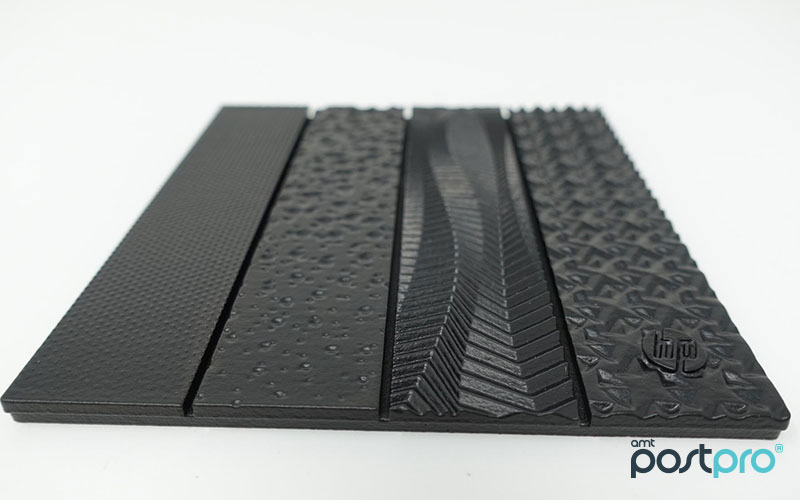

New post-processing service for your 3D parts with the PostPro3D® machine. With this new service, Erpro Group now offers a surface finish identical to injection molding techniques for your 3D parts.

This process is used on 3D parts from laser sintering technologies or HP Multi Jet Fusion. Note that this technology can also be used on FDM / FFF parts Contact us for a tailor-made quote.

Multi Jet FusionLaser sintering

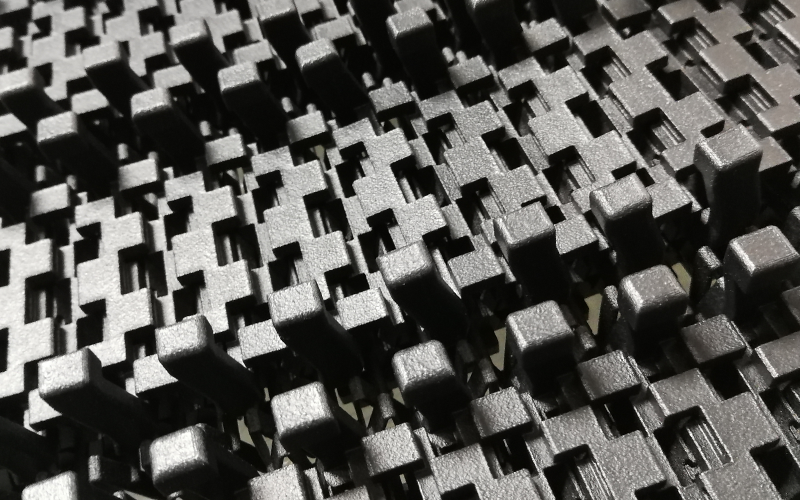

PostPro3D® can achieve a surface finish with an RA of less than 1 micron.

PostPro3D® is a technology based on AMT’s proprietary BLAST ™ process (Boundary Layer Automated Smoothing Technology). The processing chamber measures 600 x 400 x 400 mm and allows simultaneous processing of large batches of several parts.

Benefits of the BLAST ™ process

The BLAST ™ process protects the surface of 3D parts against liquid or gas penetration and does not degrade the mechanical properties of the parts.

Also, the treated 3D parts do not exhibit a cytotoxic effect in accordance with ISO 10993-5, ISO 10993-1 and ISO 10993-12 standards. Therefore, the treated parts can be certified for medical use.

Technology tested and approved for a wide range of consumer products, from sportswear to medical applications, automotive to aerospace.