ERPRO 3D FACTORY

Founded in 2017, Erpro 3D Factory is our factory of the future. Brands such as CHANEL, STELLANTIS, NOGS trust us to ensure the production of their project in large series

Technology 3D

Laser Sintering (SLS)Multi-jet fusion (MJF)CARBON® DLS™Liquid Crystal Magna (LCD)Metal Binder JettingPrecious Metals smelting (LBM)

Our success story

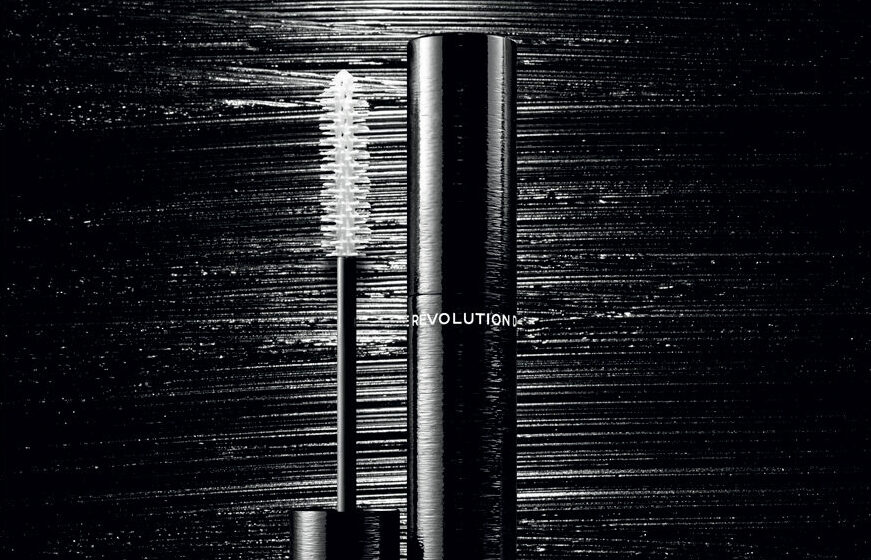

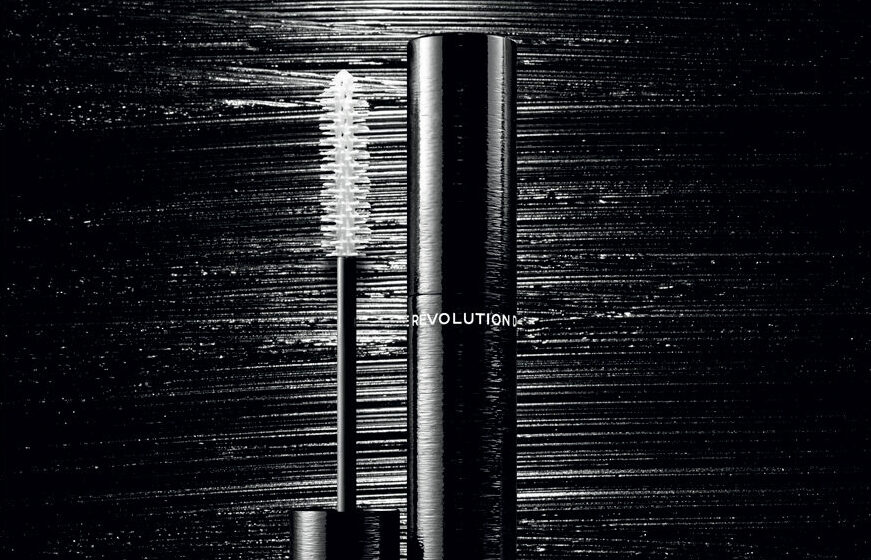

Le Volume Révolution de Chanel

The world’s first 3D-printed brush “Le Volume Révolution de Chanel” was created in-house, from biosourced polyamide thanks to our laser sintering technology. This is how we printed 10 million brushes between 2018 and 2019.

Technology: SLS

Matérial: PA11 biosourcé

Le Volume Stretch de Chanel

The brush of the “Le Volume Stretch de Chanel” mascara was printed from biosourced polyamide using our laser sintering technology. A new 3D brush for maximum flexibility. 8 million brushes printed between 2019 and 2020.

Technology: SLS

Material: biobased PA11

E.Y.E de Chanel

Chanel’s E.Y.E “Express Your Ego” service is a personalized service that exclusively offers a collection of 10 brushes with 363 possible combinations. Since the launch of the E.Y.E service, we have printed 400,000 brushes.

Technology: SLS

Matérial: PA11 biosourcé

Atol Zen Glasses

The Senior Care Atol ZEN smart glasses have the mission of detecting the falls of the elderly. These aim to bring well-being and serenity to the elderly by launching an automatic alert in the event of a fall.

Technology: MJF

Matérial: PA11 biosourcé

Flowerbomb 15th Anniversary Haute Couture Edition

For Viktor & Rolf, we made 15 unique bottles. This limited edition combines traditional craftsmanship with new 3D technologies. The set is 3D printed using Carbon® CLIP™ technology.

Each component is then polished and assembled by hand

Technology : Carbon® CLIP™

Matérial: Epx 82

Myfit Solutions Tips

For the French start-up Myfit Solutions, we have been printing custom-made tips for earphones since 2019.

Technology: Carbon® DLS™

Matérial: SIL 30

CES Innovation Awards 2020