Success Stories

CHANEL / ATOL / PEUGEOT / MYFIT / L’OREAL

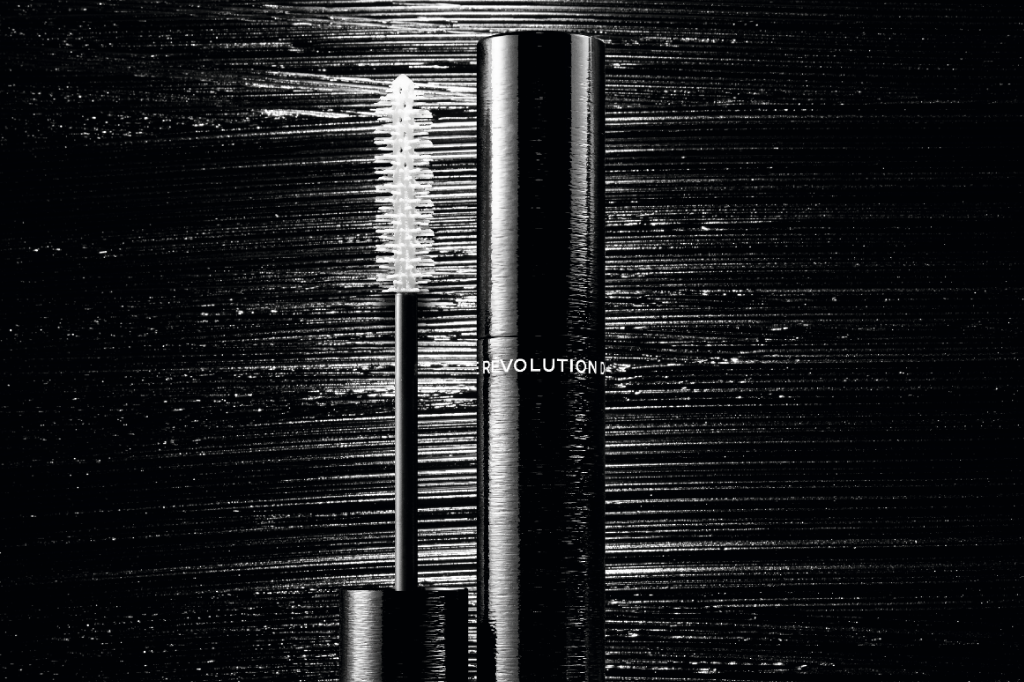

Le Volume Révolution Chanel

The world’s first 3D-printed brush “Le Volume Révolution de Chanel” was created in-house, from biosourced polyamide thanks to our laser sintering technology. This is how we printed 10 million brushes between 2018 and 2019.

PA11 Biosourcé

Technology SLS

Le Volume Stretch de Chanel

The brush of the “Le Volume Stretch de Chanel” mascara was printed from biosourced polyamide using our laser sintering technology. A new 3D brush for maximum flexibility. 8 million brushes printed between 2019 and 2020.

Material: biobased PA11

E.Y.E de Chanel

Chanel’s E.Y.E “Express Your Ego” service is a personalized service that exclusively offers a collection of 10 brushes with 363 possible combinations. Since the launch of the E.Y.E service, we have printed 400,000 brushes.

Material: Biobased PA11

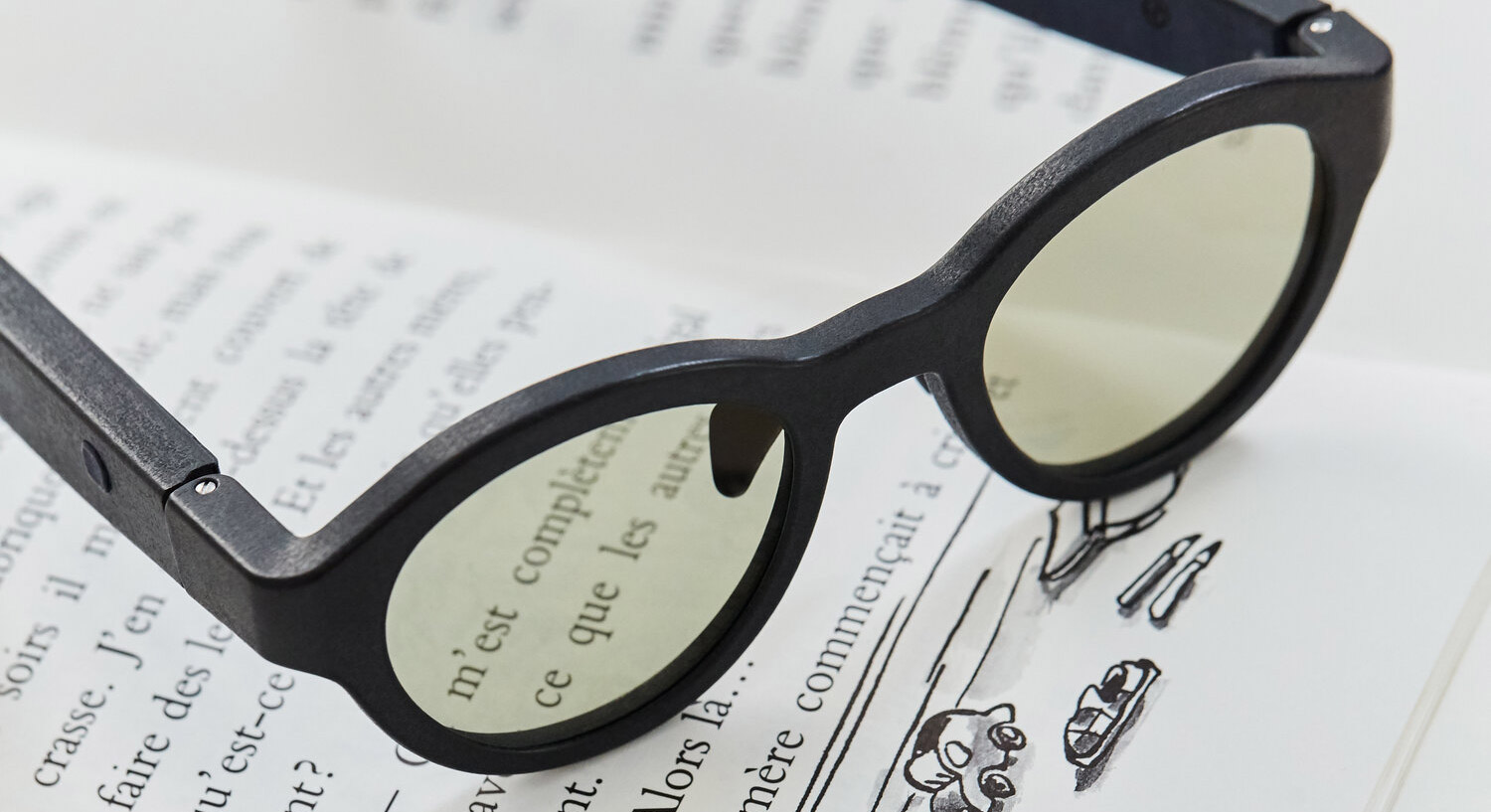

Lexilens Glasses

We supported the start-up Abeye, incubated by Atol Les Opticiens, in the Lexilens project by printing glasses in biosourced PA11 using MJF technology. Lexilens glasses are designed to make it easier for dyslexic children to read.

Material: Biobased PA11

Atol Zen Glasses

The Senior Care Atol ZEN smart glasses have the mission of detecting the falls of the elderly. These aim to bring well-being and serenity to the elderly by launching an automatic alert in the event of a fall.

Material: Biobased PA11

C-BLOCK – COLD PAD

This heavy duty bonded mechanical fastener is designed for concrete surfaces. In order to provide sufficient transverse flexibility and to obtain a relatively high stiffness in tension, an intermediate 3D-printed deformation layer is introduced between the metal fastener and the concrete surface. The 3D pattern and repetitive micro-structures generate the required macroscopic anisotropy.

Material: PA11

TORGOS – OPUS

Torgos is an innovative rocket engine developed by Opus AerospaceT. Combining advanced technology and ecology, it constitutes a unique rocket engine in the world.

Made of aluminum metal additive printing, it is powered by hydrogen peroxide and propane to provide clean propulsion for Mésange, the suborbital rocket from the OPUS company.

Material: AS7G06 ( Aluminum)

2016 Olympics Handlebars

3D printing of metal handlebars for the French Cycling Federation. Designed by Christophe Cadalbert, an engineer from GIE S2A, this unique handlebar concept is inspired by profiles from aeronautics. Tested and approved by athletes, they were used during the 2016 Olympic Games in Rio.

Material: Aluminum

Myfit Solutions

For the French start-up Myfit Solutions, we have been printing custom-made tips for earphones since 2019.

This personalization is possible thanks to the Myfit Solutions application which allows people’s ears to be scanned. From this file, we launch the 3D printing.

Material: SIL 30

CES Innovation Awards 2020

Flowerbomb – Viktor & Rolf

Pour Viktor & Rolf, nous avons réalisé 15 flacons uniques. Cette édition limitée combine artisanat traditionnel et nouvelles technologies 3D. La parure est imprimée en 3D via la technologie Carbon® DLS™.

Chaque composant est ensuite poli et assemblé à la main

Matériau: EPX 82

Accessories – Peugeot 308

Design of a new range of flexible accessories with complex shapes for the new Peugeot 308.

Material: TPU